Industry 4.0 – Asset LifeCycle Management

the customer

Voith Paper is the biggest manufacturer of paper machines in the world. Voith plants have a total length of 500 m and more. 10,000 maintenance points are not uncommon.

the task

To increase machine uptime, the plants are provided with an ALM* system that contains a mix of predictive maintenance and regular maintenance intervals.

*Asset LifeCycle Management

the solution

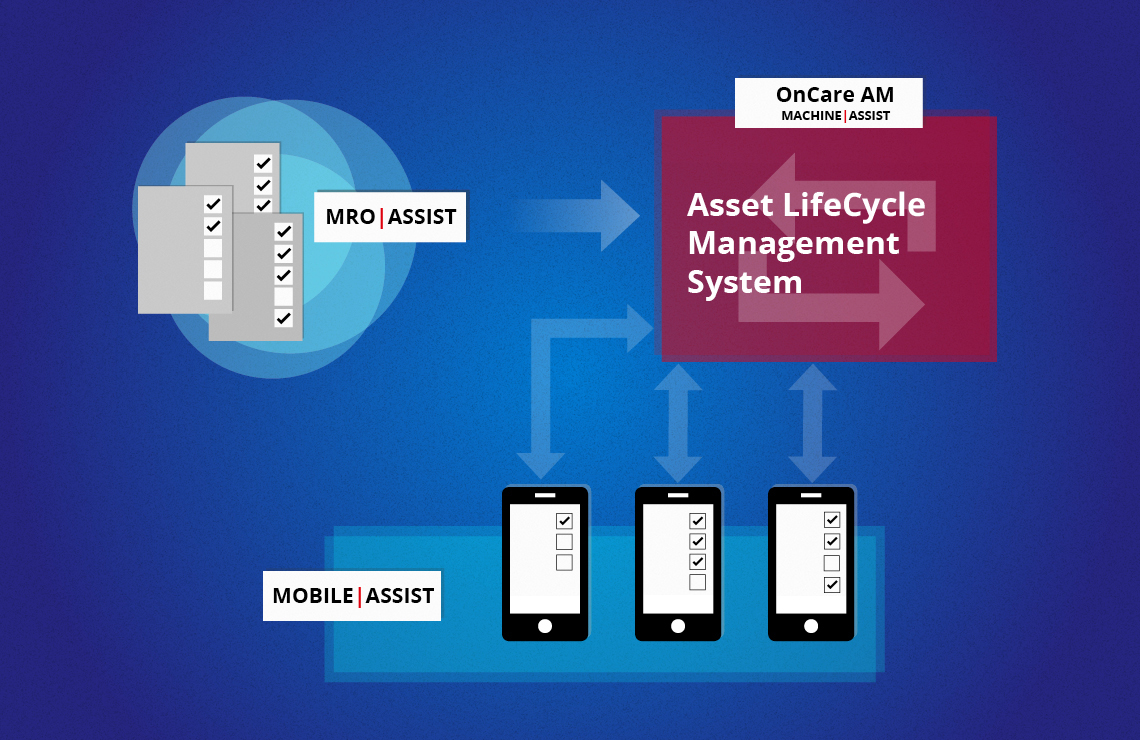

Maintenance plans, replacement parts requirement lists and maintenance parts lists are created by Voith Paper for each plant based on the SAP parts list – extensively automated by MRO | ASSIST.

The maintenance parts lists are transferred to the ALM OnCare Asset system and connected to the Condition Monitoring Systems. OnCare Asset is a further development of MACHINE | ASSIST for Voith Paper and Voith Hydro.

Dispatchers and gatekeepers work on the ALM control station of OnCare Asset to create maintenance and repair notifications for the service technicians. They receive their orders on their smartphone via MOBILE | ASSIST. For complex service orders such as roll changes, Gantt charts support the dispatchers when planning and directing several service technicians. A dashboard keeps maintenance control informed via KPIs and order status.

the details

- Industry 4.0 in maintenance – predictive maintenance, networking between manufacturers and operators

- Consistent system – from the ERP parts list to maintenance management system

- Web-based with mobile maintenance providing access to operators, manufacturers, suppliers

- Customizable based on the ASSIST Framework

- Import interfaces to SAP, JD-Edwards Enterprise One

- Interface to storage and replacement part systems

- Export of maintenance plans in XML format for other maintenance systems such as Maximo and SAP EAM

- PUSH system: Maintenance notifications, repair notifications, notifications from Condition Monitoring Systems

- PULL System: graphic searches in the maintenance parts lists for film, assembly drawings, wiring diagrams, service descriptions

- Identification of maintenance assembly groups for the service technicians using QR Codes or RFID

your contact

Wolfgang Kastenhuber

Dipl.-Mathematiker (diploma in Mathematics), Managing Director

Tel. +49 89 89053-100

Mobile +49 171 351 53 51

E-mail w.kastenhuber@paradigma-software.de